Leave us a message

Get in touch with our team and we will be happy to help you.

Stainless Steel C Groove Steel

Channel Steel

Product Description

The stainless steel channel is a long strip steel whose cross-sectional shape is a groove shape. Same as I-beam, stainless steel channel steel is also divided into two kinds of ordinary channel steel and light channel steel. The main purpose of hot-rolled stainless steel ordinary channel steel is: ordinary channel steel is mainly used for building structure, vehicle manufacturing and other industrial structures, and is often used in conjunction with I-beam.

Hot-rolled stainless steel light channel steel (YB164-63) Hot-rolled light channel steel is a kind of steel with wide legs and thin walls, which has better economic effect than ordinary hot-rolled channel steel. Main uses: construction and steel frame structure, etc.

Product Parameters

|

Material |

A36,St37,S235J0,S235J2,St52,16mn,S355JOQ195,Q215,Q235B,Q345B,S235JR,S355JR,S355,SS440,SM400A,SM400BA572,GR50,GR60,SS540 |

|

Scope of production |

50*37*4.5-400*104*14.5,75*40*3.8*7-152*76*6.4*9, 140*60*7*10-200*75*8.5*11.5 |

|

Length |

6m, 9m, 12mor according to customer requirements |

|

Technology |

Hot rolled, welded |

|

Standard |

ASTM,AISI,JIS,GB, DIN,EN |

|

Surface |

Galvanized, painted;or according to your requirements |

|

supply capacity |

2000tons/Day |

|

Business Type |

Manufacturer |

|

Certificate |

ISO, SGS,BV |

|

Application |

Widely used in building structures and engineering construction, such as room beams, ship beams, industrial furnaces, etc. |

|

loading port |

Any port in China |

|

Packaging |

Standard export packing or as your request |

|

Payment Method |

Wire transfer, spot letter of credit, Western Union, payment documents, acceptance documents, PayPal. |

Factory appearance

The company strictly follows national quality standards and establishes a full-process quality control system. From the procurement of raw materials, the supplier qualification review and factory inspection are implemented. Precision CNC equipment and automated testing instruments are used in the production process to monitor the mechanical properties, chemical composition and surface treatment process of metal materials in real time to ensure that the products meet national standards.

Packing and delivery

The company has built a closed-loop service system of "pre-sales-sales-after-sales": free technical consultation and solution design are provided before sales to assist customers in accurate selection; during sales, visual tracking of the entire order process is implemented, and customers can query production progress and logistics dynamics in real time through exclusive accounts; after-sales guarantee policies are implemented, and quality issues are responded to and handled within 48 hours.

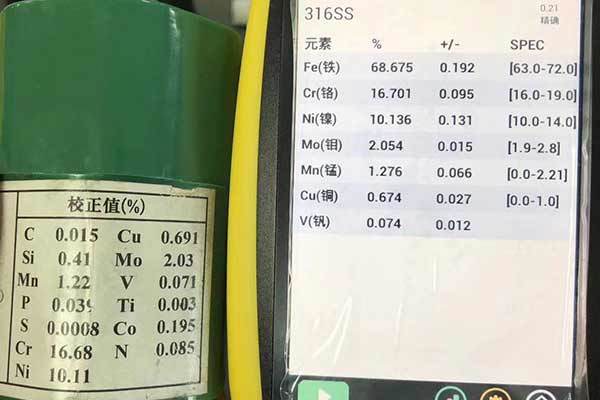

Detection

Detection

Detection

Detection

Detection

Detection

Q: How can I get your quotation as soon as possible?

Q: How do you guarantee your products?

Q: Do you accept third party inspection?

Q: Will you deliver on time?

Q: Are you a trading company or manufacturer?

Q: Will you deliver on time?

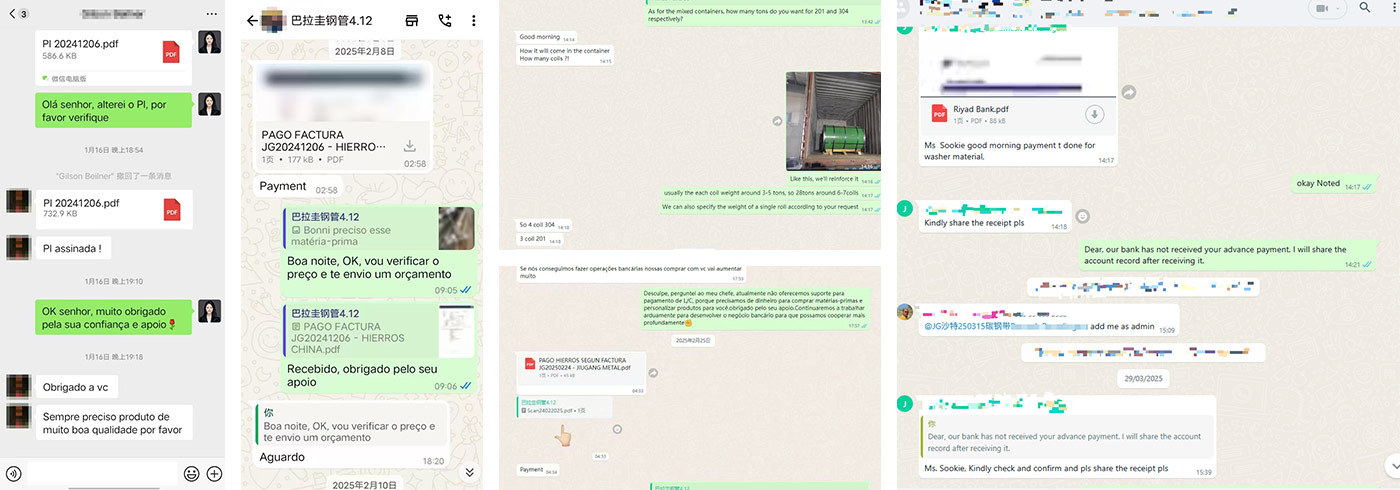

CUSTOMER TESTIMONIALS

Customer Reviews

APPLICATION AREAS

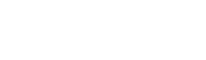

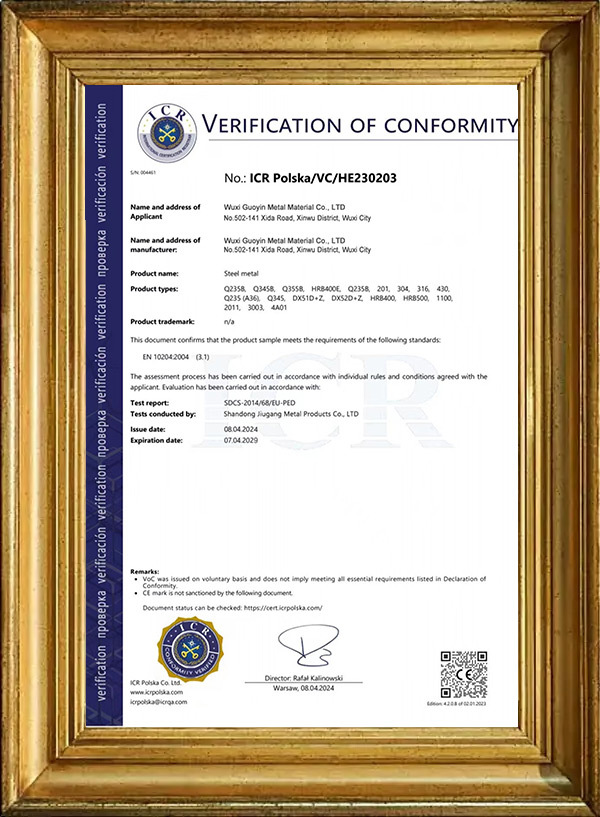

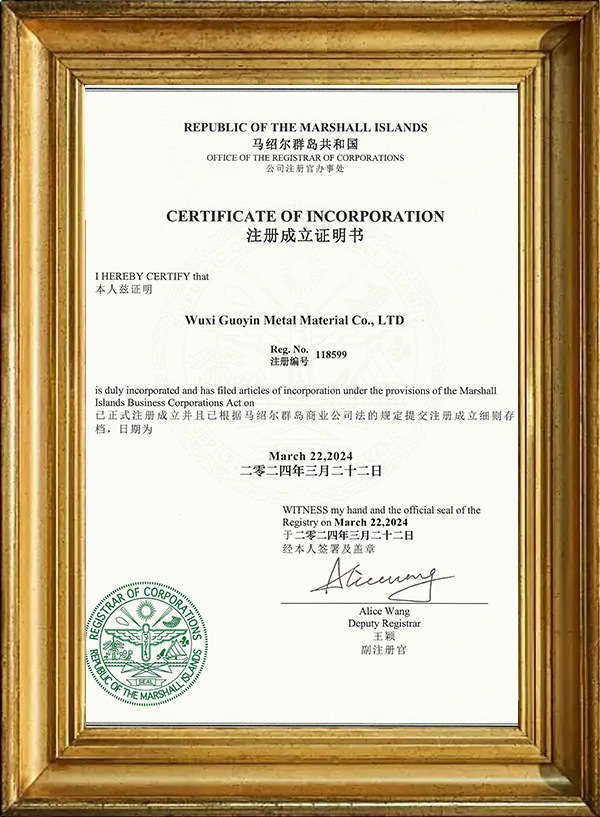

CERTIFICATES

RELATED PRODUCTS

GET A FREE QUOTE