Leave us a message

Get in touch with our team and we will be happy to help you.

316L Stainless Steel Pipe

Stainless Steel Pipe

316L Stainless Steel Pipe Description

316L stainless steel is an austenitic stainless steel metal alloy that contains nickel and molybdenum, making it corrosion resistant. 316L is a 316 low carbon grade. This grade is not affected by sensitization (grain boundary carbide precipitation). It is often used for large-gauge welded parts (approximately over 6mm). 316L stainless steel has higher creep, fracture stress and tensile strength than chromium nickel austenitic stainless steel at high temperature.

Product Parameters

Product Name | 316L Stainless Steel Pipe | |

Type | Steel Pipe | |

Outer diameter | Round Tube | 4mm-200mm |

Square Tube | 10*10mm-100*100mm | |

Rectangular Tube | 10*20mm-50*100mm | |

Wall Thickness | 0.6mm-6.0mm | |

Length | 1-6 meters, Length can be customized | |

Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

Surface | Black, Bright Polished, Rough Turning, Matt Surface Treatment, No. 4. BA, etc. | |

Scope of Application | Common applications for stainless steel pipes include food processing, Textile operations, Breweries, Water treatment plants, Oil and gas processing, Fertilizers and pesticides, Chemical applications, Construction, Pharmaceuticals, Auto parts, etc. | |

Certificate | ISO, SGS, BV, etc. | |

Production Technology | Hot Rolling, Cold Rolling | |

Edge Processing | Edging, Trimming | |

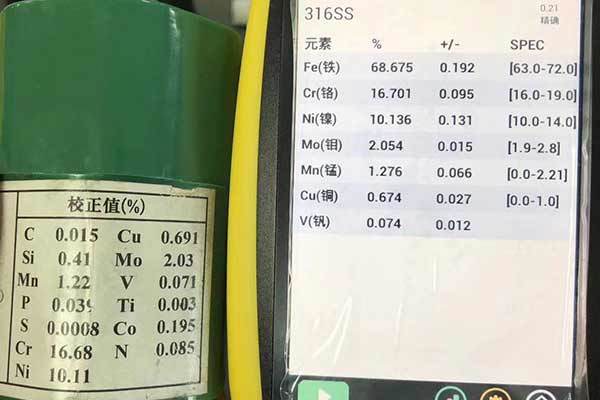

Chemical Composition

C | Si | Mn | Cr | Ni | S | P | Mo |

≤ 0.03 | ≤1.0 | ≤ 2.0 | 16.0~18.0 | 10.0~14.0 | ≤ 0.03 | ≤ 0.045 | 2.0~3.0 |

Mechanical Properties

Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

≥480 | ≥177 | ≥ 40 | ≤ 187HB;≤ 90HRB;≤ 200HV |

Physical Performance

Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

7.99 | 193 | 16.0 | 16.2 | 74 |

Factory appearance

The company strictly follows national quality standards and establishes a full-process quality control system. From the procurement of raw materials, the supplier qualification review and factory inspection are implemented. Precision CNC equipment and automated testing instruments are used in the production process to monitor the mechanical properties, chemical composition and surface treatment process of metal materials in real time to ensure that the products meet national standards.

Packing and delivery

The company has built a closed-loop service system of "pre-sales-sales-after-sales": free technical consultation and solution design are provided before sales to assist customers in accurate selection; during sales, visual tracking of the entire order process is implemented, and customers can query production progress and logistics dynamics in real time through exclusive accounts; after-sales guarantee policies are implemented, and quality issues are responded to and handled within 48 hours.

Detection

Detection

Detection

Detection

Detection

Detection

Q: How can I get your quotation as soon as possible?

Q: How do you guarantee your products?

Q: Do you accept third party inspection?

Q: Will you deliver on time?

Q: Are you a trading company or manufacturer?

Q: Will you deliver on time?

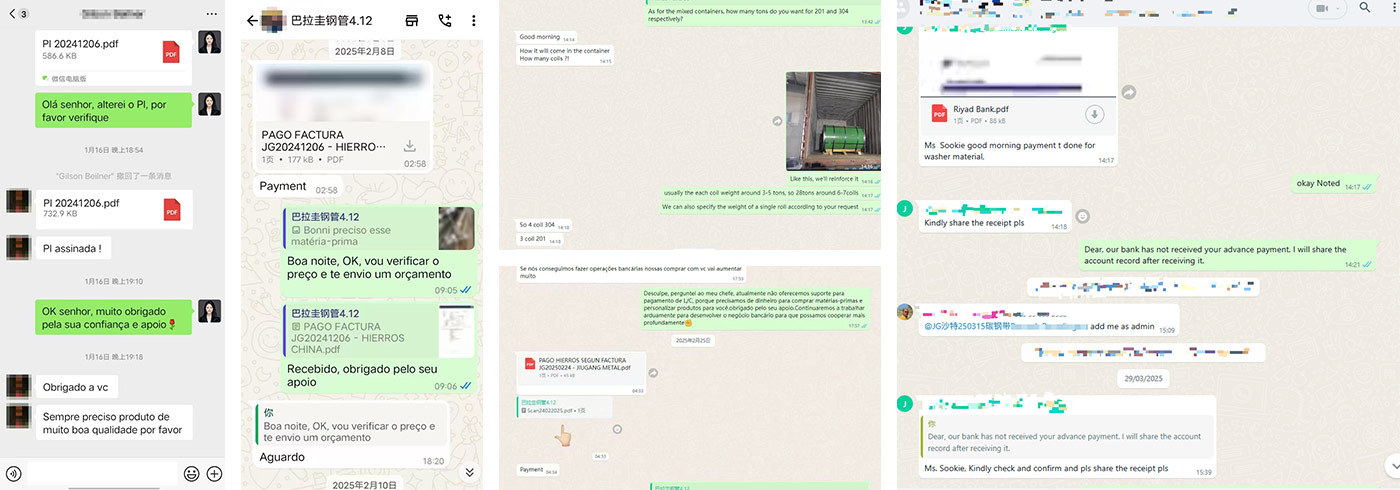

CUSTOMER TESTIMONIALS

Customer Reviews

APPLICATION AREAS

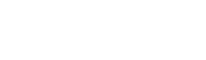

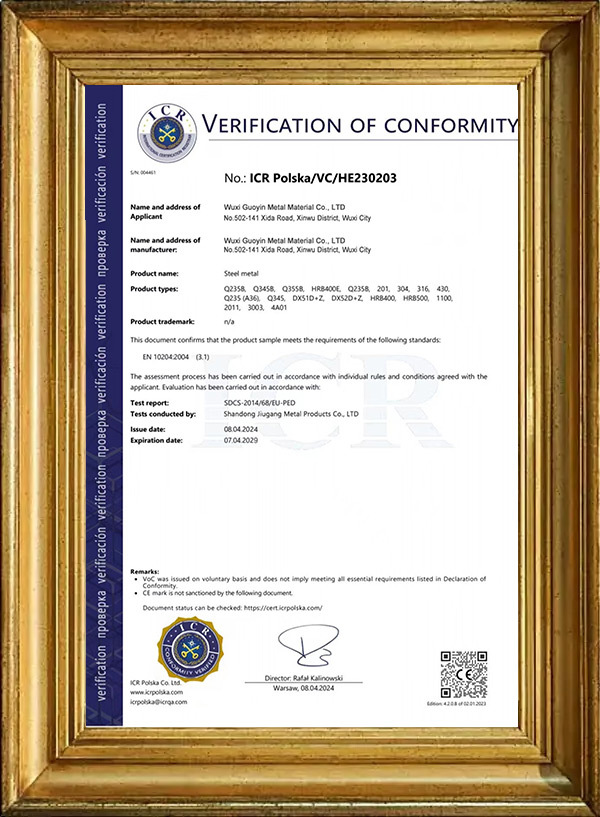

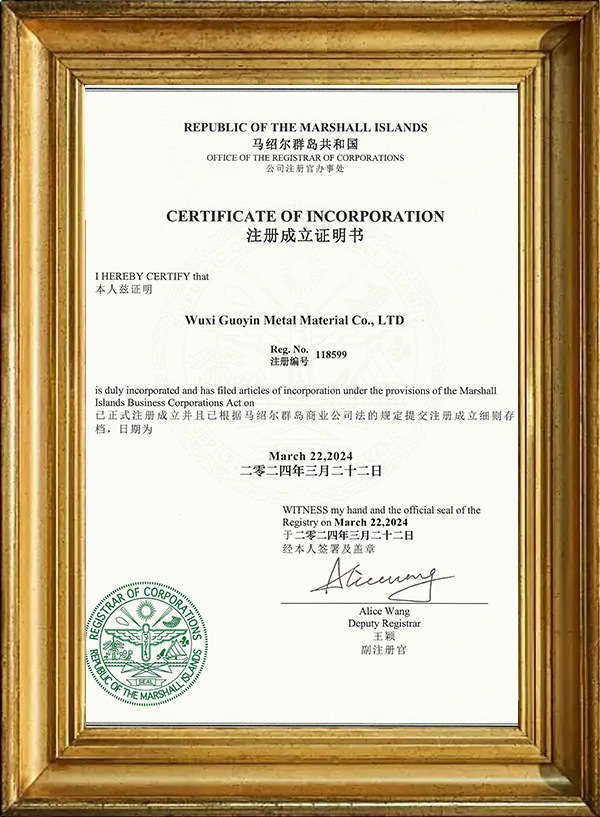

CERTIFICATES

RELATED PRODUCTS

GET A FREE QUOTE