Leave us a message

Get in touch with our team and we will be happy to help you.

A633 Carbon Steel Coil

Carbon Steel Coil

A633 Carbon Steel Coil Description

ASTM A633 steel includes four grades: A, C, D, and E, of which the thickness of grade C can reach 4 inches and the thickness of grade E can reach 6 inches. ASTM A633 steel specification is based on the standard specification for standardized high-strength low-alloy structural steel plate, which requires high notch toughness under low temperature conditions.

Product Parameters

Product Name | A633 Carbon Steel Coil |

Production Process | Hot Rolling, Cold Rolling |

Material Standards | AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

Width | 45mm-2200mm |

Length | Custom Size |

Thickness | Hot Rolling: 2.75mm-100mm |

Delivery Conditions | Rolling, Annealing, Quenching, Tempered or Standard |

Surface Process | Ordinary, Wire Drawing, Laminated Film |

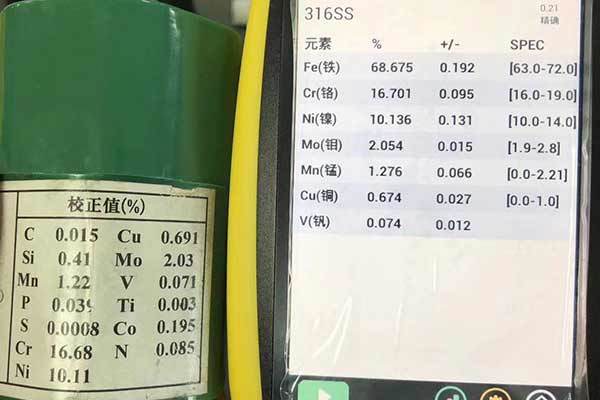

Chemical Composition

A633 | C | Mn | P | S | Si | V | Nb |

GradeA | ≤ 0.18 | 1.00-0.35 | 0.035 | 0.04 | 0.15-0.50 | - | ≤ 0.05 |

GradeC | ≤ 0.20 | 0.15-0.50 | 0.035 | 0.04 | 0.15-0.50 | - | 0.01-0.05 |

GradeD | ≤ 0.20 | 0.70-1.35 | 0.035 | 0.04 | 0.15-0.50 | - | - |

GradeE | ≤ 0.22 | 1.15-1.50 | 0.035 | 0.04 | 0.15-0.50 | 0.04-0.11 | - |

Mechanical Properties

A633 | Yield Strength | Tensile Strength | Elongation 200mm, min% | Elongation 50mm, min% | ||||

65mm | 65-100mm | 100-150mm | 65mm | 65-100mm | 100-150mm | |||

Grade A | 290 | 290 | - | 430-570 | 430-570 | - | 18 | 23 |

Grade C&D | 345 | 315 | - | 485-620 | 450-590 | - | 18 | 23 |

Grade E | 415 | 415 | 380 | 550-690 | 550-690 | 515-655 | 18 | 23 |

Physical Performance

Physical Performance | Metric | Imperial |

Density | 7.75g/cc | 0.280 lb/in³ |

Scope of Application

ASTM A633 steel plate is mainly used in petroleum, chemical, power station, boiler and other industries, for the production of reactors, heat exchangers, separators, spherical tanks, oil and gas pipelines, liquefied gas tanks, shell nuclear reactor pressure, boiler drums, liquefied petroleum gas cylinders, high pressure water pipes, water turbines and other equipment and components.

Factory appearance

The company strictly follows national quality standards and establishes a full-process quality control system. From the procurement of raw materials, the supplier qualification review and factory inspection are implemented. Precision CNC equipment and automated testing instruments are used in the production process to monitor the mechanical properties, chemical composition and surface treatment process of metal materials in real time to ensure that the products meet national standards.

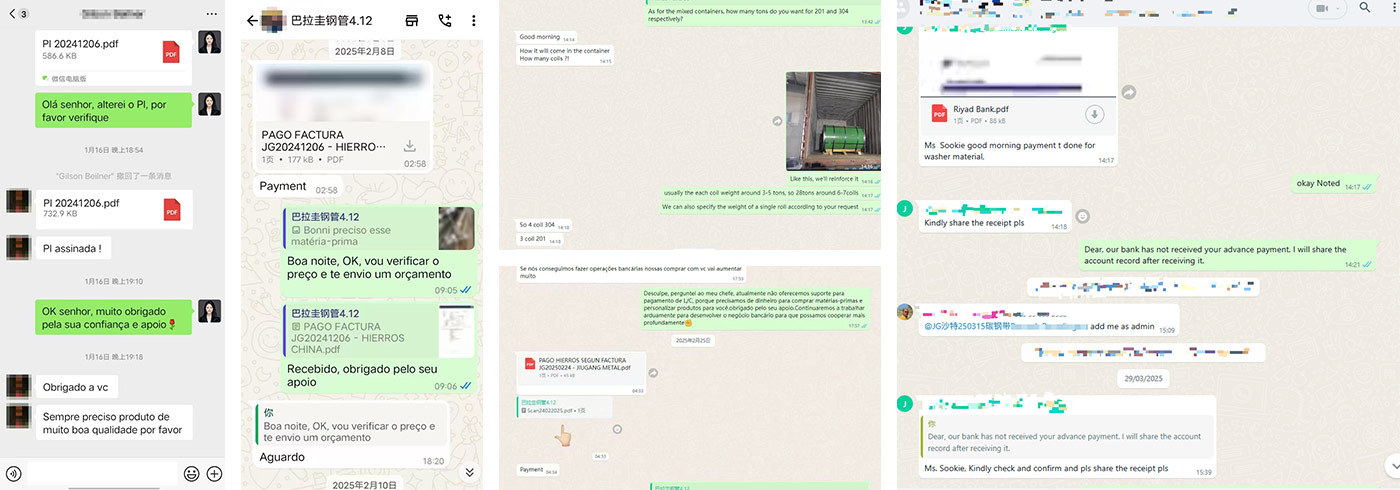

Packing and delivery

The company has built a closed-loop service system of "pre-sales-sales-after-sales": free technical consultation and solution design are provided before sales to assist customers in accurate selection; during sales, visual tracking of the entire order process is implemented, and customers can query production progress and logistics dynamics in real time through exclusive accounts; after-sales guarantee policies are implemented, and quality issues are responded to and handled within 48 hours.

Detection

Detection

Detection

Detection

Detection

Detection

Q: How can I get your quotation as soon as possible?

Q: How do you guarantee your products?

Q: Do you accept third party inspection?

Q: Will you deliver on time?

Q: Are you a trading company or manufacturer?

Q: Will you deliver on time?

CUSTOMER TESTIMONIALS

Customer Reviews

APPLICATION AREAS

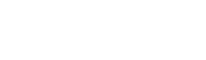

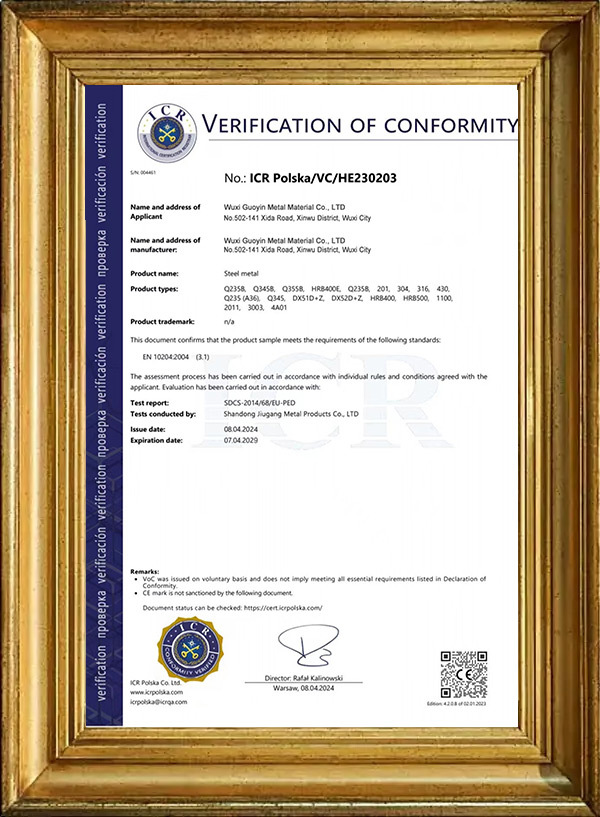

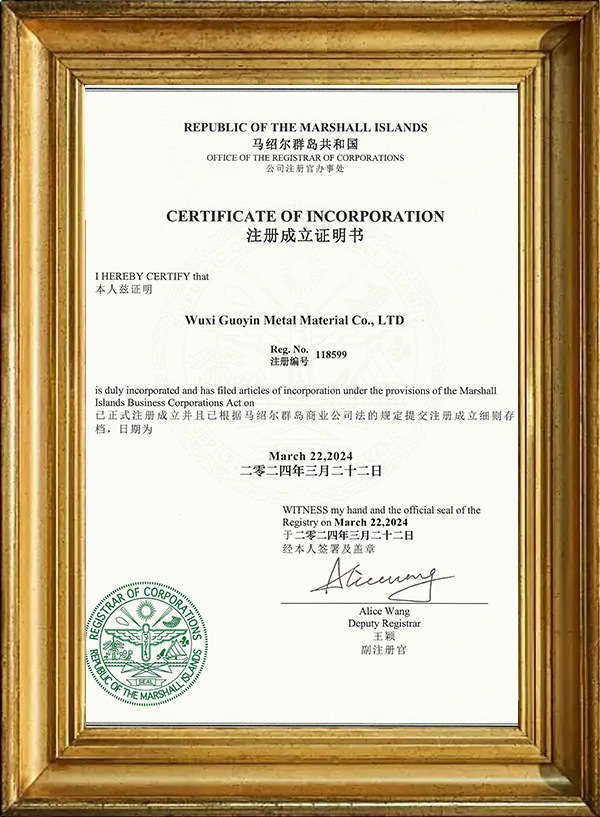

CERTIFICATES

RELATED PRODUCTS

GET A FREE QUOTE